The DTF Gangsheet Builder has revolutionized the custom apparel and textile printing landscape, offering a dynamic solution for creating high-quality prints with remarkable efficiency. This innovative tool allows users to design and organize multiple graphics seamlessly onto a single sheet, optimizing the printing process and significantly reducing material waste. As more businesses adopt Direct-to-Film (DTF) printing, understanding how to leverage the DTF Gangsheet Builder effectively becomes crucial for achieving stunning and vibrant results. With its capability to produce long-lasting prints across various fabric types, the DTF Gangsheet Builder empowers designers and printers alike to push the boundaries of creativity in apparel printing. In this article, we will delve into practical DTF gang sheet tips designed to enhance your experiences and output quality.

The concept of using a Gangsheet Builder in DTF printing introduces an efficient method for crafting vivid, custom designs on textiles. Often referred to as direct-to-film technology, this approach streamlines the production process, allowing for multiple graphics to be consolidated on one printable sheet. This not only conserves ink and media but also accelerates the overall workflow, making it an attractive option for those in the garment and fabric printing industry. By exploring various strategies and best practices for utilizing gang sheets, businesses can elevate their textile printing game while maintaining high standards for quality output. In this guide, we will provide insights into maximizing the potential of your DTF printing projects using this versatile tool.

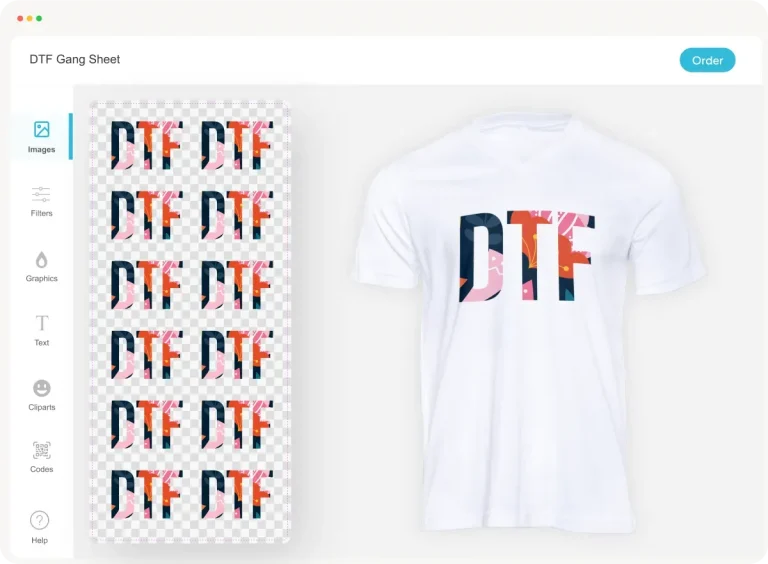

Maximizing Efficiency with DTF Gangsheet Builder

The DTF Gangsheet Builder is a revolutionary tool that streamlines the DTF printing process, enabling designers and printing businesses to create vibrant fabrics with multiple prints in a single run. By optimizing layout and arrangement, users can enhance their production efficiency, saving both time and resources. The gang sheet approach not only reduces material waste but also allows for better utilization of printer capabilities, making it an indispensable element for businesses looking to increase their output without sacrificing quality.

To further maximize efficiency while using the DTF Gangsheet Builder, it’s crucial to familiarize yourself with its features. Users can easily drag and drop designs, resize them, and adjust placement for optimal print results. Understanding the template guidelines within the builder can also help achieve a more balanced and professional layout. Additionally, planning ahead by selecting which designs to combine and ensuring adequate spacing between graphics can drastically improve the final print quality.

Essential Tips for High-Quality DTF Printing

When venturing into DTF printing, quality should always be the top priority. High-quality prints stem from meticulous file preparation, where the choice of images is critical. Using high-resolution files with at least 300 dpi ensures that the final printed products are sharp and clear. Moreover, opting for PNG files allows for transparent backgrounds, which is essential for a clean transfer onto various fabric types. This attention to detail in file preparation significantly enhances the overall quality of prints, making the designs stand out.

In addition to using high-resolution files, designers should explore various color palettes and test how they appear on different fabrics before finalizing their designs. This experimentation can lead to discovering combinations that resonate with target audiences, ensuring that final garments are not just visually appealing but also marketable. Effective use of color management tools and techniques can further guarantee that the printed colors match those intended, which is crucial in maintaining brand consistency.

Understanding the Importance of Color Management in DTF Printing

Color management is a key component in DTF printing, ensuring the accuracy and vibrancy of the final products. It involves controlling the reproduction of colors throughout the printing process, from design to the finished print. Regular calibration of monitors and printers plays a vital role in achieving consistent results. By setting up color profiles that are specific to the DTF printer in use, users can enhance their print quality, leading to products that meet the desired color expectations.

Furthermore, working with various color settings during test prints can help identify the best profiles for specific designs. For example, testing different inks, printing speeds, and temperatures can yield different results in color fidelity and saturation. Keeping detailed records of successful test prints allows designers to replicate optimal settings for future projects, significantly improving the overall quality of output and reducing trial-and-error time.

Best Practices for File Preparation in DTF Printing

Proper file preparation is crucial to achieving high-quality prints in DTF printing. Start with selecting high-resolution graphics that can withstand scaling; vector graphics are particularly preferred for their scalability. By utilizing files that remain sharp at any size, users prevent blurriness and ensure that the final print appears polished and professional. Additionally, understanding the characteristics of the DTF process will help in selecting graphics that contrast well with fabric colors, enhancing visibility and overall impact.

Users should also test various file formats and graphics to assess their compatibility with DTF printers. Ensuring that all files meet the printer’s specifications prevents issues during the print process. Additionally, consider testing different color palettes on screen, as this not only aids in selecting attractive combinations but also provides insight into how colors will appear on finished garments. By investing time in proper file preparation, users set the foundation for creating stunning prints.

Conducting Effective Testing and Prototyping

Testing and prototyping are essential steps in the DTF printing process, allowing for the fine-tuning of settings to achieve high-quality prints. Starting with test prints on sample fabrics can help anticipate how designs will look on the final product. This step enables users to adjust parameters such as ink density, printing speed, and temperature settings before committing to larger runs. Such adjustments can play a significant role in avoiding costly mistakes and material waste.

Documenting the settings used during test printing is equally crucial. By keeping meticulous notes, users can refer back to successful print configurations, ensuring consistency in future projects. Moreover, conducting multiple test prints with different settings can reveal the best approaches tailored to specific fabrics and designs, ultimately leading to superior print quality and customer satisfaction.

Key Post-Processing Considerations for DTF Prints

After the printing and curing processes are complete, handling prints with care is essential for maintaining quality. Allowing prints to cool down thoroughly helps prevent smudging or misalignment, which can detract from the overall appearance of the finished product. It’s advisable to store prints flat and away from direct sunlight to maintain vibrancy and avoid damage before application.

Additionally, conducting a final quality check before shipping or utilizing prints for apparel is a smart practice. Inspecting designs for clarity, consistency, and alignment ensures that every product meets the expected standards. By prioritizing post-processing care, businesses can enhance their production workflow and foster a reputation for delivering exceptional quality in every print.

Frequently Asked Questions

What is the DTF Gangsheet Builder used for in DTF printing?

The DTF Gangsheet Builder is a powerful tool designed to optimize the creation of gang sheets for Direct-to-Film (DTF) printing. It allows users to efficiently arrange multiple designs on a single sheet, enhancing productivity while reducing material waste and costs.

How can I ensure high-quality prints when using the DTF Gangsheet Builder?

To achieve high-quality prints with the DTF Gangsheet Builder, ensure you use high-resolution images (at least 300 dpi) in PNG format. Properly preparing your files, calibrating color settings, and conducting test prints are critical steps to ensure vibrant and durable outcomes.

What are some DTF gang sheet tips for effective file preparation?

For effective file preparation with the DTF Gangsheet Builder, use vector graphics when possible, check for compatibility with your DTF printer’s software, and experiment with different color palettes to find the best visual results on fabric.

Why is color management important in DTF printing?

Color management is crucial in DTF printing because it ensures the colors seen on-screen accurately represent the final product. Regular calibration of monitors and printers, along with using appropriate color profiles for your DTF printer, will greatly improve print output quality.

What common mistakes should I avoid when using the DTF Gangsheet Builder?

Common mistakes to avoid include overcrowding designs on the gang sheet, ignoring the use of high-resolution files, and skipping test prints. These errors can result in misalignment, blurry prints, and wasted materials, undermining the quality of your DTF printing.

How do I properly cure ink after DTF printing for optimal durability?

To achieve optimal durability in DTF printing, curing the ink properly is essential. Use a heat press to apply even heat and pressure, ensuring you adjust the temperature and duration according to the specific fabric type while allowing prints to cool down before handling.

| Key Points | Details |

|---|---|

| Overview | DTF printing revolutionizes custom apparel by efficiently producing high-quality prints with the DTF Gangsheet Builder, optimizing designs on a single sheet. |

| Understanding DTF Printing | DTF printing transfers designs onto fabrics using specialized inks, allowing vibrant prints on various materials. |

| Utilizing the Gangsheet Builder | The Gangsheet Builder enables efficient arrangement of multiple designs, saving time and material. |

| File Preparation | Prepare files using high-resolution images (300 dpi) and PNG format for best results. |

| Color Management | Calibrate monitors and printers to ensure accurate color representation in final prints. |

| Testing and Prototyping | Conduct test prints and fine-tune parameters to achieve desired print quality. |

| Curing the Ink | Ensure proper heat application during curing for durable prints that resist wear. |

| Post-Processing Tips | Allow prints to cool before handling and store away from direct sunlight. |

| Common Mistakes to Avoid | Avoid overcrowding designs, using low-res files, and skipping test prints for quality assurance. |

Summary

The DTF Gangsheet Builder is an essential tool in creating high-quality prints for custom apparel. By effectively utilizing this technology, users can streamline their printing process, ensuring optimal design placement while minimizing waste. Mastery of file preparation, color management, testing, and curing techniques will lead to exceptional print outputs that are vibrant and durable. Adhering to the best practices outlined here will not only enhance production efficiency but also help businesses meet the growing demands of the market.