UV DTF transfers have revolutionized the printing landscape, providing businesses with cutting-edge solutions that challenge traditional printing methods. This innovative technology excels in print quality, delivering vibrant, high-resolution images across a broad spectrum of materials, from textiles to plastics. Not only do these prints showcase superior durability, resisting fading and environmental damage, but they also offer unmatched material versatility, catering to diverse needs. Additionally, UV DTF transfers prove to be cost-effective, especially for smaller projects, as they require less setup time and minimal labor. In this article, we will delve into the advantages of UV DTF transfers compared to traditional printing techniques, helping you choose the best method for your specific requirements.

When exploring printing technologies, you may come across terms like direct-to-film transfers or UV printing, both of which refer to the rapidly evolving methods that promise impressive results. These advanced printing solutions offer excellent print resolution and longevity, making them appealing to businesses seeking reliable and flexible printing options. Unlike more conventional techniques that can be limited in application, modern transfer methods boast a wide range of compatibility, allowing for creative freedom across various substrates. Furthermore, these approaches are particularly advantageous for smaller runs due to their streamlined processes and reduced costs. In this discussion, we will highlight the strengths of these contemporary printing technologies in comparison to traditional methods.

Understanding UV DTF Transfers: A Modern Printing Solution

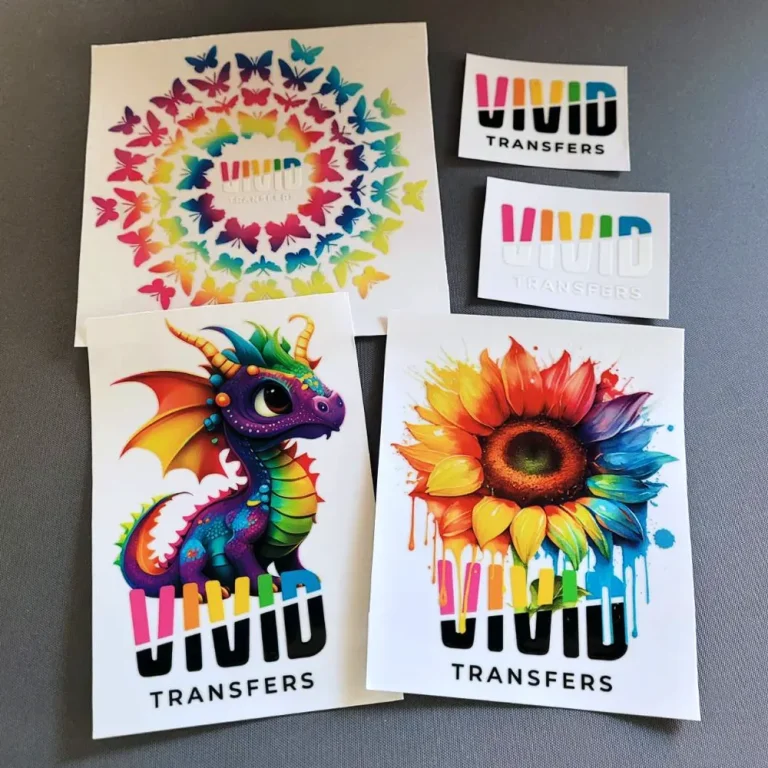

UV DTF transfers, or Direct-to-Film transfers, are a revolutionary printing technology that allows for vibrant and detailed prints on various substrates. Unlike traditional printing methods that often require specific materials, UV DTF transfers can be utilized on textiles, plastics, and metals, highlighting their exceptional material versatility. This flexibility makes them particularly appealing for businesses aiming to offer customized products, as they can print on an array of surfaces without compromising on quality.

Moreover, the print quality achievable with UV DTF transfers is among the highest available today. These transfers leverage advanced ink technology to create high-resolution images that retain intricate details and colors, providing a photographic quality that surpasses many traditional methods. This capability is especially valuable for designers looking to produce intricate or multi-colored artwork, as it enables them to maintain visual integrity across different materials.

Durability of UV DTF Transfers Compared to Traditional Printing

One of the standout features of UV DTF transfers is their remarkable durability. The use of UV-cured inks enhances resistance to fading, scratching, and environmental damage, ensuring that prints maintain their vivid colors over time. This longevity is particularly advantageous for products exposed to sunlight or harsh conditions, as UV DTF transfers offer a longer life span compared to traditional printing techniques that may begin to fade in similar environments.

In contrast, while traditional printing methods can yield durable results as well, they often require specific inks and substrates to achieve optimal longevity. For instance, screen printing on certain fabrics may not withstand prolonged exposure to UV light as effectively as UV DTF prints. Therefore, businesses that prioritize durability in their products may find UV DTF to be the more reliable option.

Material Versatility: The Edge of UV DTF Transfers

The versatility of materials that can be printed using UV DTF technology is unparalleled. From fabrics to hard surfaces like wood and metal, businesses can leverage UV DTF transfers to cater to various markets and product types. This adaptability not only broadens the potential customer base but also allows for innovative product designs that incorporate multiple materials, enhancing creativity and brand options.

Traditional printing methods, while effective, often come with restrictions based on the substrate used. For example, methods like offset printing are primarily designed for paper products, thus limiting the range of applications. In contrast, UV DTF transfers break through these barriers, enabling printers to offer customized solutions that use various materials, which is a vital aspect for businesses that evolve with consumer trends.

Print Quality: A Closer Look at Differences

When evaluating print quality, UV DTF transfers stand out for their ability to produce strikingly vivid and high-resolution images. This modern technique accurately reproduces intricate designs with a level of detail and color accuracy that rivals traditional printing methods. Thanks to advanced printing technology, UV DTF enables the creation of photo-quality images that are ideal for promotional items, fashion products, and art reproductions.

In contrast, traditional printing methods, such as screen printing, often require multiple setups for color separation, which can compromise the detail and overall print quality for complex designs. Each print method has its merits, but businesses focusing on high-detailed artwork or multiple color layers would likely benefit more from the precision offered by UV DTF transfers.

Cost-Effectiveness of UV DTF vs. Traditional Printing

Cost-effectiveness is a crucial consideration when choosing a printing method, especially for small to medium-sized businesses. UV DTF transfers excel in this area, as the setup is typically less labor-intensive than traditional methods. With quicker production times and fewer preliminary costs, businesses can efficiently manage expenses while meeting customer demands for custom prints.

On the other hand, traditional printing becomes more cost-effective only at higher volumes, where initial setup costs can be spread out over a larger number of prints. For businesses with ongoing large order needs, traditional methods might present a better long-term investment, especially if they have the capacity to handle the longer lead times and preparation involved.

Current Trends: Embracing UV DTF Technology in Printing

As the printing industry evolves, the introduction of UV DTF technology has sparked significant interest among businesses seeking innovative and efficient solutions. The technology addresses the growing demand for faster turnaround times and customization options, making it an attractive choice for modern consumers. With its ability to produce high-quality prints on various materials, UV DTF is becoming a staple for companies aiming to stay competitive.

Additionally, many printing services are now integrating UV DTF transfers into their existing offerings. By combining this modern technology with traditional methods, they can offer consumers a wider range of products while ensuring high-quality output and maintaining operational efficiency. This integration signals a broader industry shift towards embracing advanced printing solutions that meet consumers’ ever-changing needs.

Frequently Asked Questions

What are the primary advantages of UV DTF transfers compared to traditional printing?

UV DTF transfers offer several advantages over traditional printing, including superior print quality with vibrant colors and intricate details, enhanced durability due to UV-cured inks that resist fading and scratching, and remarkable material versatility, allowing prints on textiles, plastics, and metals. These benefits make UV DTF technology an appealing choice for businesses seeking flexibility and high-quality results.

How do UV DTF transfers ensure better print quality than traditional printing methods?

UV DTF transfers provide better print quality due to the high-resolution capabilities of modern printers and the use of UV-cured inks. These inks allow for a wider color gamut and maintain sharp details essential for complex designs, while traditional printing methods often require multiple color separations which can compromise quality.

Are UV DTF transfers more durable than traditional printing methods?

Yes, UV DTF transfers are generally more durable than many traditional printing methods. The UV-cured inks used in this process provide excellent resistance to fading, scratching, and environmental factors, ensuring a longer lifespan for the printed materials. In contrast, traditional methods may be more prone to wear and discoloration over time.

What makes UV DTF transfers a cost-effective option for smaller print jobs?

UV DTF transfers are cost-effective for smaller print jobs due to lower initial setup costs and minimal labor required. This efficiency allows for quick production runs without the significant investment of time and resources typical in traditional printing methods, making it ideal for custom orders and small batches.

Can UV DTF transfers be applied to various materials like traditional printing?

Absolutely! One of the standout features of UV DTF transfers is their remarkable material versatility. They can be applied to a wide range of substrates, including textiles, plastics, and metals, which is often a limitation for traditional printing methods that are suited for specific materials alone.

How does the setup process for UV DTF transfers compare to traditional printing processes?

The setup process for UV DTF transfers is typically more straightforward and quicker than traditional printing processes. It requires specific printers and a heat press but allows for rapid production cycles, especially beneficial for small runs. Traditional methods often involve more complex setups and longer lead times, which can affect overall efficiency.

| Criteria | UV DTF Transfers | Traditional Printing |

|---|---|---|

| Print Quality | High-resolution, vibrant colors, ideal for complex designs. | High quality but can struggle with detailed, colorful designs due to multiple screens in screen printing. |

| Durability and Longevity | Highly durable, resistant to fading and scratching due to UV-cured inks. | Durability can vary; generally subject to fading from sunlight unless proper inks are used. |

| Material Versatility | Compatible with textiles, plastics, metals; very versatile for various products. | Limited to fabric for screen printing; others like lithography are for paper products. |

| Print Process and Setup | Straightforward setup with specialized printers and heat press; suitable for small runs. | More extensive preparation required; longer lead times for large quantities. |

| Cost-Effectiveness | More budget-friendly for small to medium jobs; lower initial labor costs. | More cost-effective for mass production after initial setup costs are covered. |

Summary

UV DTF transfers represent a revolutionary advancement in printing technology, offering vibrant and durable prints suitable for a multitude of substrates. Compared to traditional printing methods, UV DTF provides superior print quality and longevity, as well as unmatched material versatility, making it a compelling choice for businesses of all sizes. As the industry trends shift towards customization and sustainability, UV DTF transfers are gaining popularity for their efficiency and reduced waste. Ultimately, understanding the distinct advantages of UV DTF technology will empower businesses to make informed decisions that align with their printing needs.