The **DTF Gangsheet Builder** is revolutionizing the landscape of custom apparel printing by harnessing the power of Direct-to-Film (DTF) technology. This innovative tool allows designers and print service providers to generate multiple designs on a single sheet, maximizing efficiency while reducing overall production costs. By leveraging gangsheet technology, businesses can enjoy the benefits of vibrant, high-quality prints that can be applied to a variety of fabrics, from cotton to poly blends. Not only does this method yield cost-effective printing solutions, but it also minimizes waste—a vital factor in today’s eco-conscious environment. As the demand for custom clothing rises, understanding the advantages of DTF gangsheet benefits becomes essential for anyone in the printing industry.

The emergence of the **DTF Gangsheet Builder** marks a new chapter in garment decoration techniques, particularly in the realm of cost-effective printing methods. This technology, known for its ability to consolidate different designs into one print job, enhances efficiency and drives down expenses in custom clothing ventures. With advancements in gang sheet technology, print operations can now create stunning, high-resolution images that cater to the growing appetite for personalized apparel. The versatility of this printing approach appeals to various textile businesses, enabling them to breathe new life into their product ranges without the burden of hefty investments. By embracing gangsheet innovations, entrepreneurs and print providers can stand out in the vibrant landscape of the custom printing market.

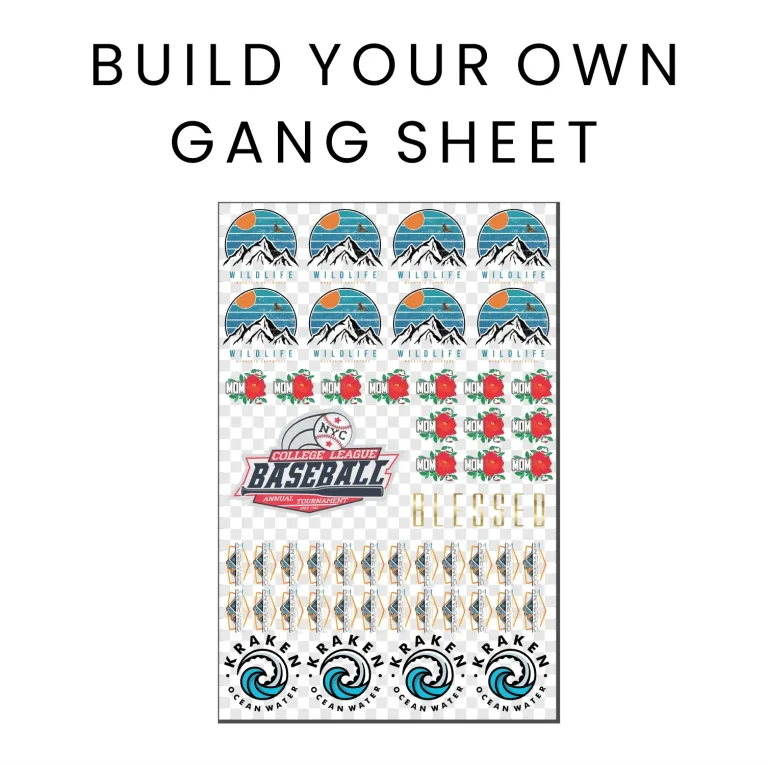

What You Need to Know About DTF Printing Technology

Direct-to-Film (DTF) printing technology has revolutionized the landscape of custom apparel printing. Unlike traditional printing methods, DTF printing allows for vibrant, detailed designs that can be transferred onto a variety of fabrics such as cotton, polyester, and blends. This method employs a unique transfer film that is printed with eco-solvent inks, ensuring high-quality results that stand the test of time. As a growing trend, businesses engaged in custom apparel can leverage DTF technology to offer a more versatile product range without the need for multiple printing techniques.

The distinctive features of DTF printing technology make it a compelling choice for print service providers. It supports the meticulous detail and color depth that modern consumers demand, especially in an age where personalization is key. Moreover, DTF gangsheet technology takes this to the next level by allowing multiple designs to be printed simultaneously on a single sheet, reducing material waste and enhancing overall efficiency. By adopting DTF printing, businesses can significantly improve their turnaround times and meet customer expectations for both quality and speed.

Benefits of the DTF Gangsheet Builder for Custom Apparel

The DTF Gangsheet Builder presents numerous benefits for custom apparel businesses seeking cost-effective printing solutions. By consolidating various designs into one print run, businesses can drastically reduce their overall production costs while maximizing the use of printing resources. This not only lowers the cost per unit but also streamlines the entire process of design creation and execution, ensuring quicker delivery times for customers.

Furthermore, the ability to produce high-quality prints with DTF gang sheets enhances the competitive edge for print service providers. Each print generated through this technology is engineered to withstand numerous washes without compromising on vibrancy or quality. Therefore, businesses can confidently offer their customers durable and appealing apparel, fostering repeat business and building a loyal client base.

Technological Advancements in DTF Gangsheet Production

Recent innovations in the DTF Gangsheet Builder technology have made it easier than ever for businesses to manage their printing operations. Advanced software solutions now provide users with tools to optimize layouts, ensuring that multiple designs can be efficiently arranged for printing. These user-friendly interfaces require minimal technical expertise, making it accessible for a broader audience, from small startups to established print companies.

Additionally, modern DTF printers come equipped with features specifically designed for gang sheet printing, allowing for efficient handling and layout of designs. As this technology evolves, print businesses can take advantage of increased automation and precision in their operations, further enhancing productivity and reducing the chances of human error.

DTF Gangsheet vs. Traditional Printing Methods

When comparing DTF gangsheet printing to traditional methods like screen printing, the advantages become apparent. DTF printing allows for more intricate and colorful designs to be printed with greater ease and at a lower cost for smaller batches. This makes DTF particularly appealing for businesses dealing with varied and personalized orders, unlike traditional printing methods which may require a larger minimum order quantity.

Additionally, the versatility of DTF gang sheets enables businesses to experiment with diverse fabric types and product offerings, adapting to changing market trends swiftly. This flexibility is crucial in the competitive landscape of custom apparel printing, where the ability to deliver unique and high-quality products on demand is increasingly essential.

Addressing Challenges in DTF Gangsheet Printing

While the advantages of DTF gangsheet printing are significant, it’s important to acknowledge the challenges businesses may face. One primary concern is the equipment costs associated with acquiring advanced DTF printers and the necessary supplies. The initial investment might be daunting for smaller businesses, necessitating careful planning and budgeting to ensure a sustainable transition to this printing method.

Another critical challenge involves ensuring the quality of adhesives used during the transfer process. The success of a print can hinge on the right adhesive application, and businesses must take the time to select quality materials to ensure durability and satisfaction. Additionally, maintaining consistent quality across different designs printed on gang sheets may require robust quality control measures, further emphasizing the need for thorough operational protocols.

Future Trends in DTF Gangsheet Technology and Custom Printing

Looking ahead, the DTF gangsheet technology is poised to become ever more integral to the custom apparel printing market. With the ongoing shift towards personalized and on-demand production, print service providers who adopt DTF technology will find themselves better equipped to meet consumer demands for unique apparel. This trend signifies a broader movement towards embracing innovation as a means to enhance operational efficiencies and maximize output.

Moreover, as more businesses recognize the cost-effectiveness and quality of DTF gangsheet printing, we can expect advancements in materials science to further improve ink and adhesive formulations, making the process even more reliable and sustainable. With the right technological advancements, business operators can enhance their market positioning and capture the interests of a growing customer base eager for high-quality, tailored products.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it work?

The DTF Gangsheet Builder is a tool that allows users to compile multiple designs onto a single film sheet for Direct-to-Film (DTF) printing. This method enhances efficiency by reducing ink waste and production costs, making it ideal for custom apparel printing.

What are the primary benefits of using the DTF Gangsheet Builder technology in printing?

The primary benefits include cost-effective printing solutions by bundling multiple designs, high-quality durable prints that withstand washes, and versatility across various textile types. This technology is particularly advantageous for businesses with small orders or diverse custom apparel needs.

How does DTF gangsheet technology improve production efficiency?

DTF gangsheet technology improves production efficiency by allowing multiple designs to be printed simultaneously on a single sheet. This reduces the number of prints required, minimizes waste, and streamlines the custom apparel printing process, which saves both time and resources.

Can the DTF Gangsheet Builder be used for various fabric types?

Yes, the DTF Gangsheet Builder is highly versatile and can be used on a wide range of fabrics, including cotton, polyester, and blended materials. This flexibility supports businesses looking to expand their product offerings in custom apparel printing.

What should businesses consider regarding equipment when using DTF Gangsheet technology?

Businesses should consider the initial investment and maintenance costs associated with DTF printers and the quality of adhesives used. These factors are crucial to ensure effective printing and the longevity of printed designs in custom apparel applications.

How does DTF printing compare to traditional printing methods in terms of cost efficiency?

DTF printing, particularly using a gangsheet approach, offers significant cost efficiency compared to traditional methods like screen printing. By printing multiple designs at once on a single sheet, costs per unit decrease, making it an attractive option for print service providers handling large volumes or varied orders.

| Key Points | Description |

|---|---|

| What is DTF Gangsheet? | A gangsheet is a large sheet that allows multiple designs to be printed simultaneously, minimizing ink waste and streamlining production. |

| Advantages | 1. Cost Efficiency: Lowers cost per unit by bundling designs on a single sheet. 2. High Quality Prints: Produces vibrant and durable designs that withstand multiple washes. 3. Versatility: Can be applied to various textiles including cotton and polyester. |

| Advancements in Technology | Software tools have revolutionized DTF gangsheet printing, enabling easier arrangement and optimization of designs, catering to users with limited technical expertise. |

| Market Trends | Growing demand for custom apparel boosts the use of DTF printing methods, which offer efficient solutions compared to traditional printing methods like screen printing. |

| Challenges | 1. Equipment costs can be high. 2. Adhesive quality is crucial for long-lasting applications. 3. Quality control is essential to maintain consistency in large volumes. |

Summary

DTF Gangsheet Builder is changing the face of apparel printing by introducing a streamlined process that caters to the increasing demand for custom designs. With its cost efficiency and versatility, it allows businesses to print high-quality images on various fabrics while minimizing waste. As print service providers adjust to market trends favoring DTF technology, the potential for growth in this sector is immense. By adopting the DTF gangsheet method, companies can enhance their operational capabilities and meet consumer expectations for quick, customized apparel solutions. Embracing this advanced technology is key to thriving in today’s competitive print marketplace.